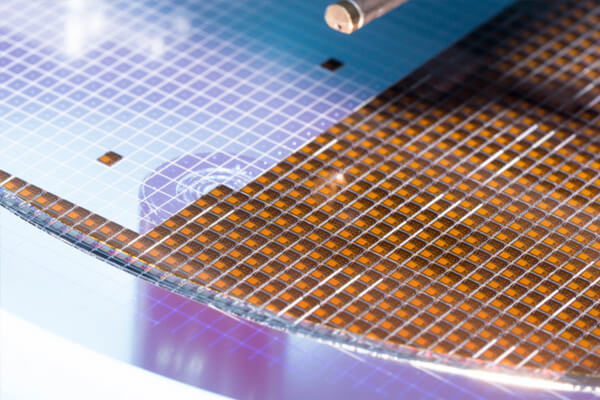

Semiconductor development and design involves a lot of elements, the design and development process will be carried out in a controlled manner. RTL design and Physical design will be carried out in the development stage. The development and design stages will be monitored by the operator. The digital section of the design can be defined by RTL programming. IoT is used to implement the data transfer and thereby we can easily determine any faults. We use Automated test equipment to check the semiconductor.

Electronic design automation is utilised to do the designing and simulation. We will be able to check several data while using the EDA. Electronic software design tools such as Proteus and Eagle will help us to execute the designing process efficiently.